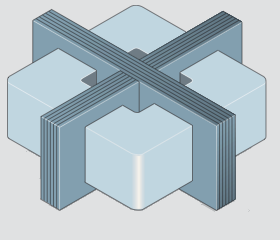

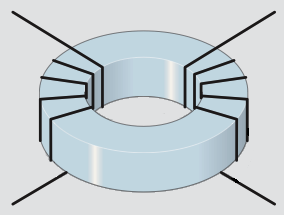

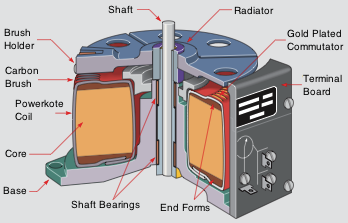

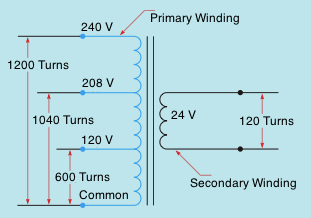

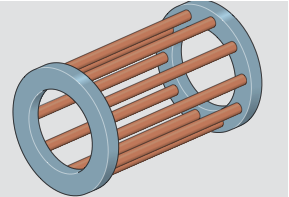

The squirrel cage motor receives its name from the type of rotor utilized in the motor. A squirrel cage rotor is made by linking bars to two end rings. If the metal lamination’s were eliminated from the rotor, the result would look very similar to a squirrel cage (shown below). A squirrel cage is a cylindrical device constructed of heavy wire. A shaft placed within the center of the cage allows the cage to spin around the shaft. A squirrel cage is put inside the cage of small animals such as squirrels and hamsters to permit them to work out by running inside of the squirrel cage. A squirrel cage rotor is shown below.

Squirrel Cage Motor

squirrel cage rotor

Concept of Operation

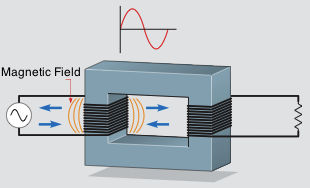

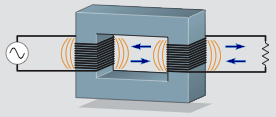

The squirrel cage motor is an induction motor. That suggests that the current flow in the rotor is produced by induced voltage from the turning magnetic field of the stator.

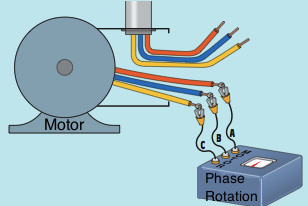

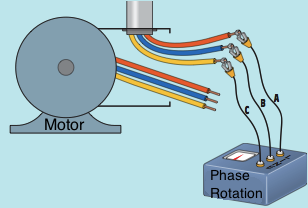

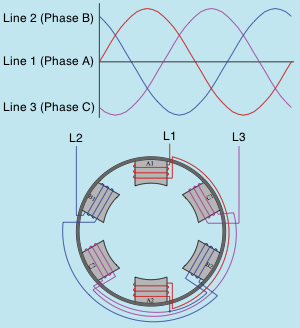

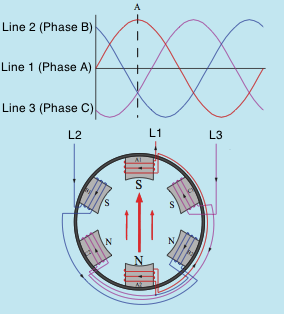

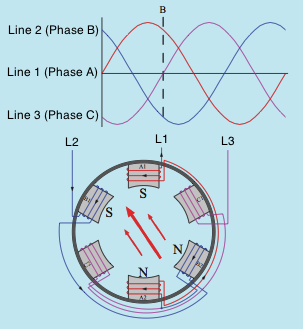

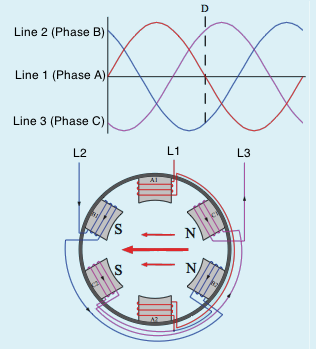

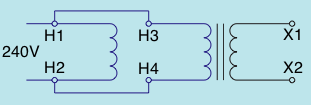

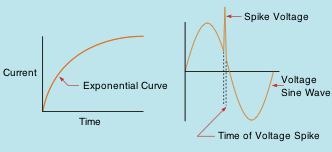

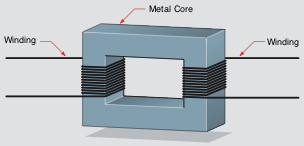

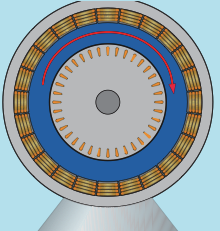

In the figure below, a squirrel-cage rotor is shown inside the stator of a three-phase motor. It will be presumed that the motor given includes 4 poles per phase, which produces a turning magnetic field with a synchronous rate of 1800 revolutions per minute. The stator is linked to a 60-hertz line. When power is first connected to the stator, the rotor is not turning. The electromagnetic field of the stator cuts the rotor bars at a rate of 1800 revolutions per minute. This cutting activity causes a voltage into the rotor bars. This induced voltage will be the same regularity as the voltage put on the stator. The quantity of induced voltage is identified by three aspects:.

1. The strength of the electromagnetic field of the stator.

2. The number of turns of wire cut by the magnetic field (in the case of a squirrel-cage rotor, this will be the number of bars in the rotor).

3. The speed of the cutting action.

induced voltage inside squirrel cage motor

Since the rotor is stationary at this time, optimum voltage is induced into the rotor. The induced voltage triggers current to stream through the rotor bars. As current flows with the rotor, an electromagnetic field is produced around each bar.

The magnetic field of the rotor is brought into the electromagnetic field of the stator, and the rotor starts to turn in the exact same direction as the turning magnetic field. As the rate of the rotor boosts, the rotating electromagnetic field cuts the rotor bars at a slower rate. For example, presume the rotor has actually increased to a speed of 600 rpm. The synchronous speed of the rotating electromagnetic field is 1800 rpm. Therefore, the rotor bars are being cut at a rate of 1200 rpm (1800 rpm – 600 rpm = 1200 revolutions per minute). Considering that the rotor bars are being cut at a slower rate, less voltage is induced in the rotor, lowering rotor current. When the rotor existing decreases, the stator current reduces also.

As the rotor continues to increase, the turning magnetic field cuts the rotor bars at a lowering rate. This decreases the quantity of induced voltage and, for that reason, the quantity of rotor current. If the squirrel cage motor is running without a load, the rotor continues to speed up till it reaches a rate close to that of the rotating magnetic field.

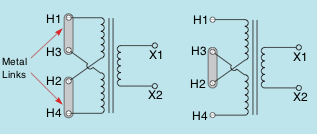

Starting Features of Squirrel Cage Motors

When a squirrel cage motor is first turned on, it has a present draw several times greater than its regular running current. The actual quantity of starting current is identified by the kind of rotor bars, the horse power rating of the motor, and the applied voltage. The kind of rotor bars is indicated by the code letter found on the nameplate of a squirrel cage motor.

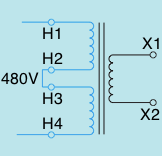

Torque

The quantity of torque produced by an AC induction motor is figured out by three factors:.

1. The strength of the electromagnetic field of the stator.

2. The strength of the electromagnetic field of the rotor.

3. The phase angle distinction in between rotor and stator fields.

Notice that one of the factors that determines the quantity of torque produced by an induction motor is the strength of the magnetic field of the rotor. An induction motor can never ever reach synchronous speed. Another element that determines the amount of torque developed by an induction motor is the phase angle distinction in between stator and rotor field flux. Maximum torque is developed when the stator and rotor flux are in phase with each other.

Check out our Facebook Page Here!